Fatigue Dynamic Testing Machine

Applications:

PWS-3 Electronic Fatigue Testing Machine is composed of main engine, electric actuator, servo motor,

electric cylinder, computer and software etc. It can be applied to dynamic performance and fatigue test of various materials, structural parts and components. It can be used for tensile, compression, dynamic low cycle fatigue, programmed fatigue, fracture mechanics and a variety of mechanical properties test.

The PWS series testing machine is the ideal equipment for dynamic testing in aerospace, aviation, transportation, metallurgy, scientific research institutes, colleges and universities.

Character:

◎ High Frame stiffness;

◎ The data acquisition system consists of four high precision 24 bit A/D conversion channels;

The highest resolution is 1/300000;

◎ Three-way photoelectric encoder input, allowing the pulse frequency of orthogonal code up to 5 MHZ;

◎ The electronic measuring system has no potentiometer and other hand-adjusting elements, which ensures interchangeability and facilitates maintenance and replacement;

◎ Built-in large-scale CPLD programmable device, with high-speed operation, real-time processing.

Key specifications:

|

Model |

PWS-3 |

||||

|

Maximum static test force |

±3KN | ||||

|

Maximum dynamic test force |

±3KN | ||||

|

Accuracy of test force |

In range 2%-100%,Accuracy:±1% | ||||

|

Frequency range |

0.1-10Hz | ||||

|

Volatility of dynamic force indicated Value |

2% | ||||

|

Maximum stroke |

±75mm, indicated accuracy: ±0.5%; | ||||

|

Flat Sample Thickness |

0-7mm | ||||

|

Round sample diameter |

Φ2~φ9mm | ||||

|

Power Supply |

Sine wave, square wave, triangle wave , serrate wave and Cosine wave | ||||

Frequency-frequency characteristics table: |

Frequency (Hz) | 1 | 2 | 5 | 10 |

| Amplitude (mm) | 2 | 10 | 4 | 2 | |

1: Host Framework

◎Main frame of two columns, hard chrome plated, effective width between columns 500mm;◎Upper beam: The ball screw on the back of the column moves up and down to adjust the test space;

◎The maximum adjustable space: 800mm;

◎Working table height: 100mm;

◎Frame stiffness: 3.3*108N/m.

2: Actuator

◎Placed above the main frame workbench;◎Maximum static test force: +/-3kN;

◎Maximum dynamic test force: +/-3kN;

◎Actuator stroke: 150mm (can be customized).

3. Sensor

◎High precision load sensor, placed on the upper beam, with pre-tensioning mechanism;

◎Displacement sensor: Measuring range 150mm, built-in actuator.

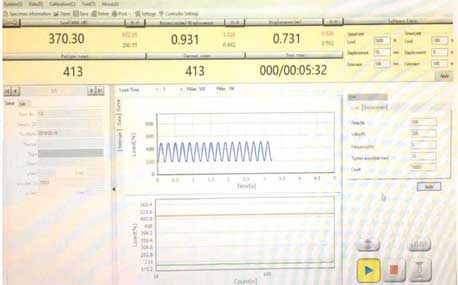

4. Control and Computer Software System

◎The control system uses Panasonic actuator; ◎Test Control Software System;

◎The test software is intuitive and readable.

Loading...