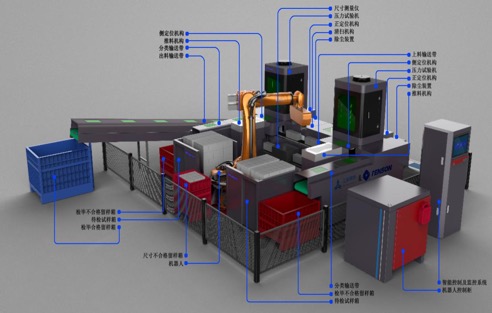

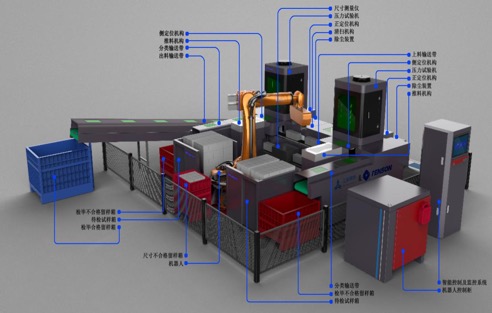

Automatic Concrete Testing Station Model TA-2000Ⅳ

Application:

Concrete compressive strength intelligent detection system is composed of sample transfer vehicle, intelligent handling unit, code scanning identification unit, size measuring instrument, pressure testing machine, cleaning and dust removal unit, classified conveyor belt, intelligent control system, abnormal alarm system, sample storage unit, protection device, video acquisition system and other complete equipment.

The test line can realize the functions of test block storage, three-dimensional dimension measurement, automatic grasping, automatic feeding, accurate placement, scanning code identification, automatic loading, video monitoring, data transmission, classification of qualified and unqualified products, cleaning and dust removal, and transportation after inspection

Intelligent concrete compressive strength detection system (one driven two system), the system can realize the whole process of intelligent loading and unloading, compressive strength detection and result judgment in the process of concrete compressive strength detection. No less than 600 groups of concrete compressive strength test can be completed within 24 hours of design capacity.

In this project, two loading stations are set up and two presses work at the same time, which can be used for testing two different specifications of specimens: 150 mm × 150 mm and 100 mm × 100 mm. The loading rate is controlled automatically according to the national standard.

There is no material dropping in the process of sample transmission. It can grasp quickly, detect pressure and rotate automatically. The whole automatic test does not need human intervention.

Work Flow:

1. Sample collection 2. Dimension measurement 3. Sample grabbing and loading 4. Specification inspection and test scanning 5. Loading 6. Unloading and conveying 7. Safety protection 8. Working environment requirements of testing machine.

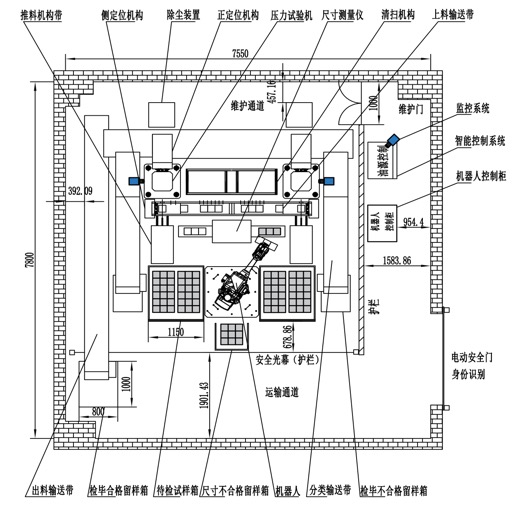

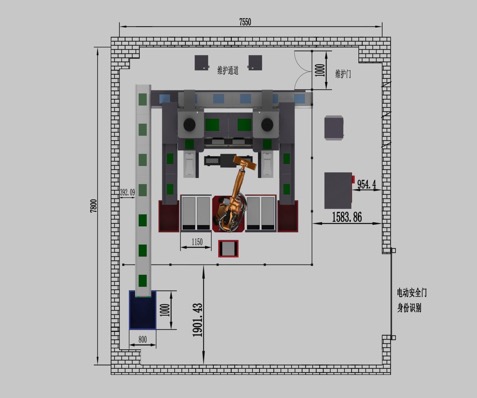

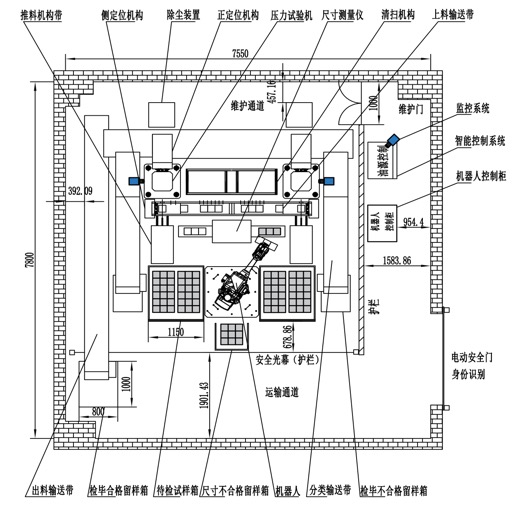

Functional Layout Diagram

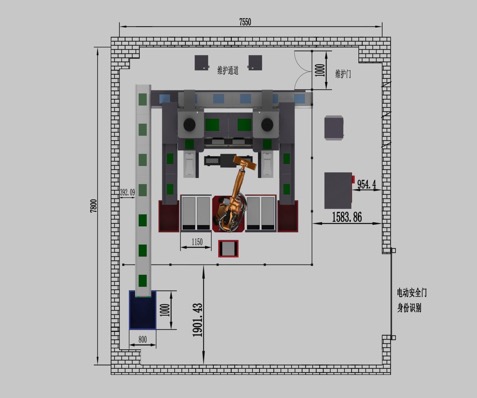

Concrete compressive strength intelligent detection system is composed of sample transfer vehicle, intelligent handling unit, code scanning identification unit, size measuring instrument, pressure testing machine, cleaning and dust removal unit, classified conveyor belt, intelligent control system, abnormal alarm system, sample storage unit, protection device, video acquisition system and other complete equipment.

The test line can realize the functions of test block storage, three-dimensional dimension measurement, automatic grasping, automatic feeding, accurate placement, scanning code identification, automatic loading, video monitoring, data transmission, classification of qualified and unqualified products, cleaning and dust removal, and transportation after inspection

Intelligent concrete compressive strength detection system (one driven two system), the system can realize the whole process of intelligent loading and unloading, compressive strength detection and result judgment in the process of concrete compressive strength detection. No less than 600 groups of concrete compressive strength test can be completed within 24 hours of design capacity.

In this project, two loading stations are set up and two presses work at the same time, which can be used for testing two different specifications of specimens: 150 mm × 150 mm and 100 mm × 100 mm. The loading rate is controlled automatically according to the national standard.

There is no material dropping in the process of sample transmission. It can grasp quickly, detect pressure and rotate automatically. The whole automatic test does not need human intervention.

Work Flow:

1. Sample collection 2. Dimension measurement 3. Sample grabbing and loading 4. Specification inspection and test scanning 5. Loading 6. Unloading and conveying 7. Safety protection 8. Working environment requirements of testing machine.

Functional Layout Diagram

Loading...