Kilo-scale Continuous Flow Microchannel Reactors

Summary

The CM-D series continuous flow reactors is a high-throughput glass microreactor processed from high borosilicate float glass. The four-layer structure design includes the heat exchanger in the reactor to reduce the space occupancy rate. The design of the structure ensures the maximization of mixing efficiency, so that the reaction phase forms multiple vortex staggered states in the reaction phase, and ensures that the reaction phase is fully mixed and reacted in the flow channel.

The CM-D series glass microchannel reactor is compatible with all reagents except hot concentrated alkali, molten alkali metal, hot concentrated H3PO4, HF, and strong corrosive agents. It can operate stably for a long time. The excellent high light transmittance can achieve short wavelength Photocatalytic reaction. Compared with the traditional tubular catalysis, the microreactor can also increase the catalysis conditions and promote the formation of reactants through the application of the heat exchange layer.

Salient features of CM-D glass flow reactor :

· Available in integrated multilayer glass construction for mixing, reaction & heat transfer.

· Micro channel with modular system to connect multiple reactors in series or parallel.

· Suitable for various liquid-liquid, gas-liquid homogeneous & multi phase reactions.

· Microreactors from glass, quartz, silicon and glass-silicon compounds.

· Useful in photochemical & UV induced reactions.

· Specially designed micro reactors used in various photochemical and UV induced reactions.

Figure of CM-D glass flow reactor:

Specifications of CM-D glass flow reactor

Specifications of CM-D glass flow reactor

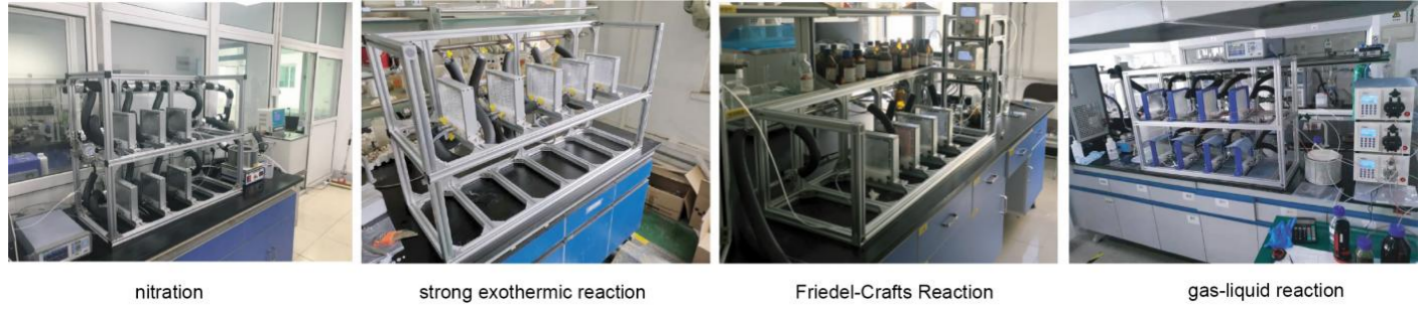

CM-D Kilo-scale Continuous Flow Microchannel Reactors Figure