TH94350 Hydraulic Servo Horizontal Tensile Testing Machine

Application:

The computer controlled electro-hydraulic servo horizontal testing machine is a kind of special high-precision testing equipment which is suitable for the tensile test , break test ,cyclic test, proof load ,elongation measurement of chain, rope, steel wire rope and electric fittings. The equipment can realize automatic operation, and the test can be completed automatically by computer software. The equipment uses load sensor and spherical centering device, and then consists of thrust cylinder, frame, lifting platform, etc. The equipment is driven by special power hydraulic source, electro-hydraulic servo control technology, computer data acquisition and processing, which can realize full-automatic closed-loop control. The equipment is composed of test host, oil source system (hydraulic power source), measurement and control system, electrical system, etc.

Main Structure Introduction

1.The main machine adopts horizontal frame structure, the stroke of oil cylinder is 2000mm, and the maximum testing space is 9000mm. The two beams with tensile fixture, fixed beam and thrust beam are precision processed with steel plate. The truss is welded with thick steel plate and processed on horizontal machining center. All auxiliary tools are finished after heat treatment of alloy steel. The overall design bearing capacity of frame structure is 5000kn, which ensures the precision, stability and reliability of the testing machine.

2.The adjustment of tensile test space is realized by moving the remote beam back and forth. For electric remote control, the beam movement can be controlled by close micro motion to make the positioning more accurate. At the same time, there is no need for manual pushing, which is fast and labor-saving. The two ends of the bolt are inserted vertically into the guide rail and the remote crossbeam by manual assistance. The operation of the bolt realizes the beam positioning and completes the space adjustment of the testing machine. It is very convenient to adjust the step distance of 500mm.

3.The high-precision load sensor used in the main engine has high comprehensive accuracy, high sensitivity and good repeatability. After random calibration, the test will not be affected by external orce, which can ensure the accuracy of the test process and parameters. Calibration and calibration are simple and convenient.

4.The machine design has been fully considered in terms of beauty, convenience and safety. For example: the test space adjustment is convenient and fast; the special fixture clamping is reliable; all parts of the testing machine are strictly antirust treated, and the surface of the pull rod is plated with hard chromium, polished and rustproof, so as to ensure the quality and beauty of the equipment, so as to satisfy the customers

Hydraulic Power System

1.The integrated oil source cabinet is composed of hydraulic pump station, oil source control, host control and computer host, which is convenient for operation, maintenance, protection and transportation. Computer, display screen and printer can be placed in the integrated measurement and control cabinet, with neat layout and space saving. The maximum working pressure of oil source system can reach 25MPa and 30MPa respectively.

2.The oil cylinder adopts the bi-directional control oil cylinder with multi-channel sealing, and the main force of the oil cylinder is the jacking force. The cylinder barrel and piston are made of high strength wear-resistant materials, which will not deform, wear and leak for a long time. High quality imported sealing ring, wear ring and dust ring are selected as sealing elements.

3.The power source adopts imported high-pressure gear pump to ensure stable system pressure and stable oil cylinder operation during long-term use. Energy saving, reliability, safety and environmental protection are fully considered in the system design. The oil source system adopts the components that meet the requirements of environmental protection.

4.The whole system adopts servo closed-loop control, high response servo valve, motor torque and speed stability, directional valve, differential valve, one-way valve, differential valve, etc, The valve core has fast response and high sensitivity, so it has good tracking, follow-up, adjustable and other functional characteristics. Under the control of high-performance measurement and control system, accurate closed-loop control is realized to ensure the test speed. It is a hydraulic servo control system with the most advanced technology, the best quality and the most high-grade configuration in the domestic testing machine.

5.The system is equipped with high-density hydraulic oil filtering system to ensure the cleanliness of medium oil under any conditions, and better ensure the optimal functional state of each hydraulic valve and servo valve;

6.The pressure self-protection function of hydraulic system ensures the potential danger caused by accidents, with high safety and reliability of human and machine.

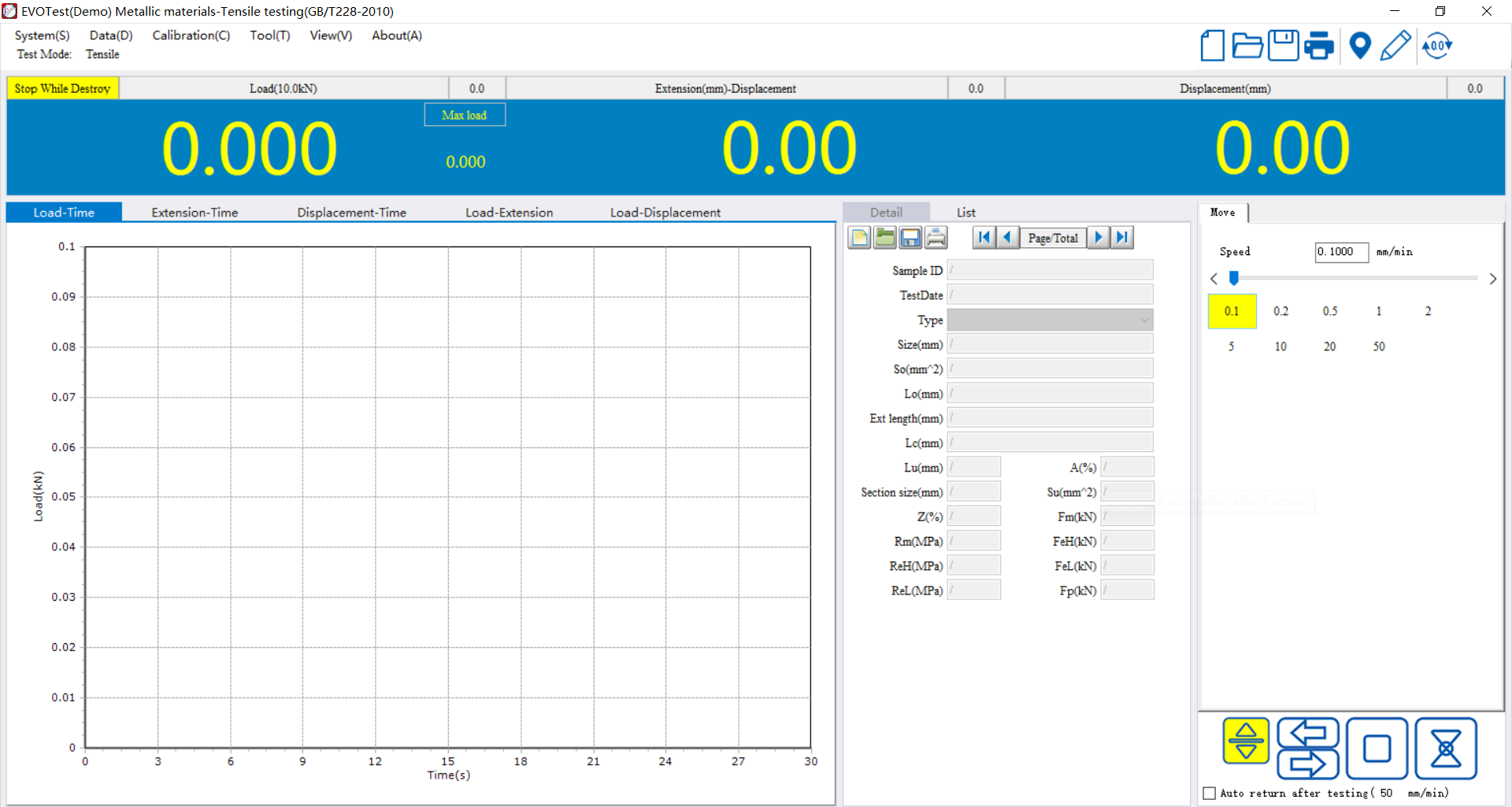

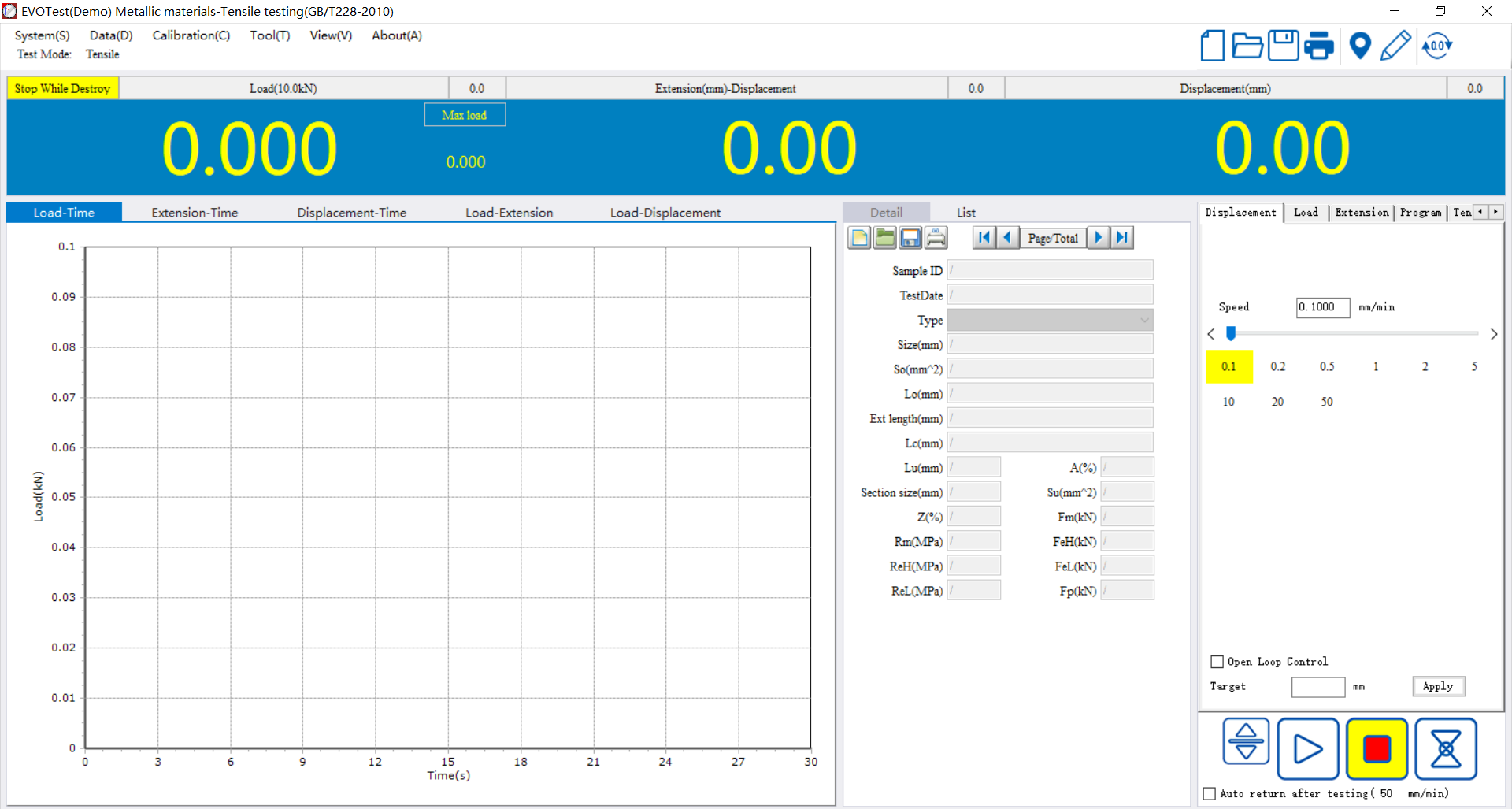

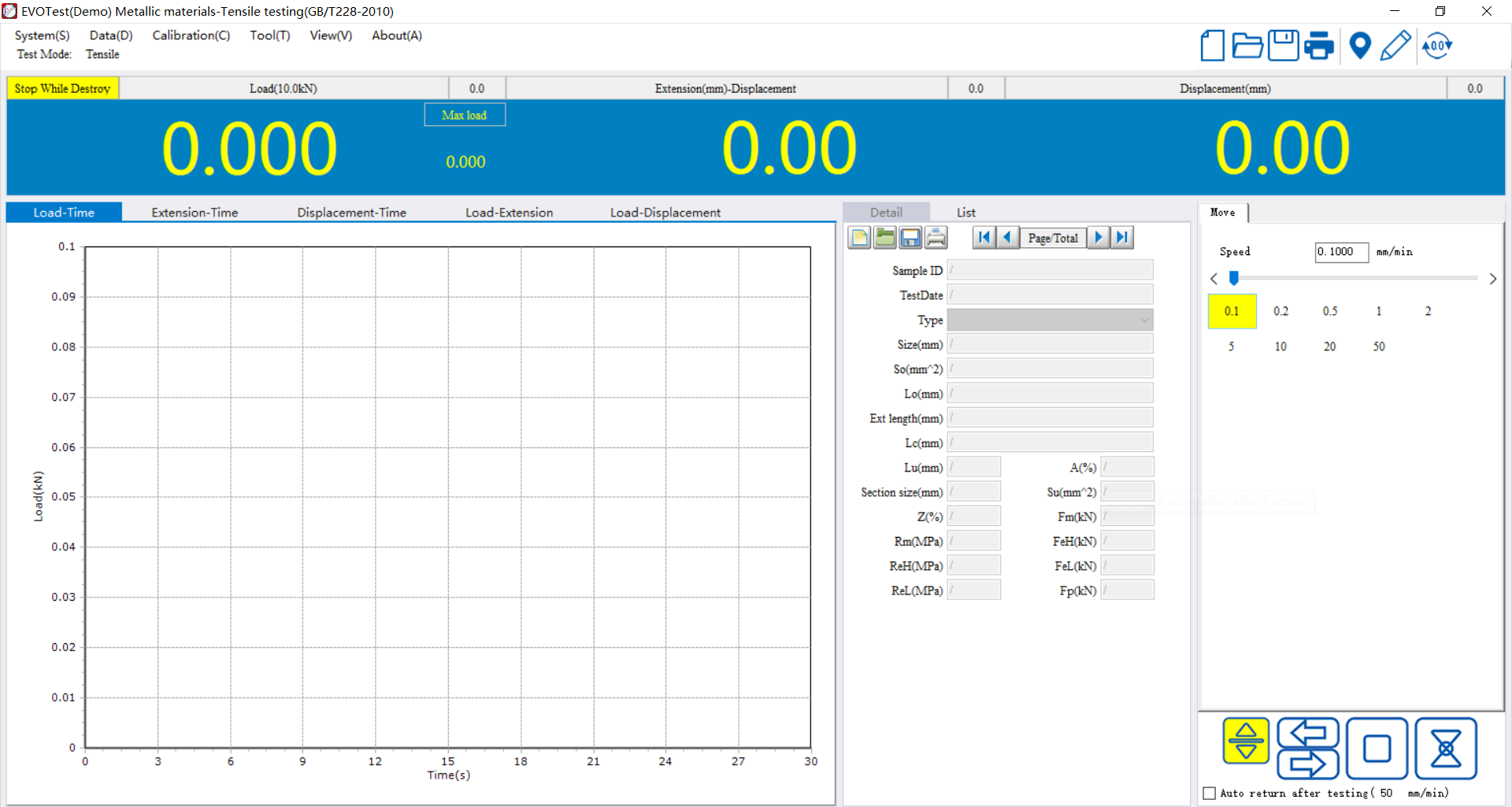

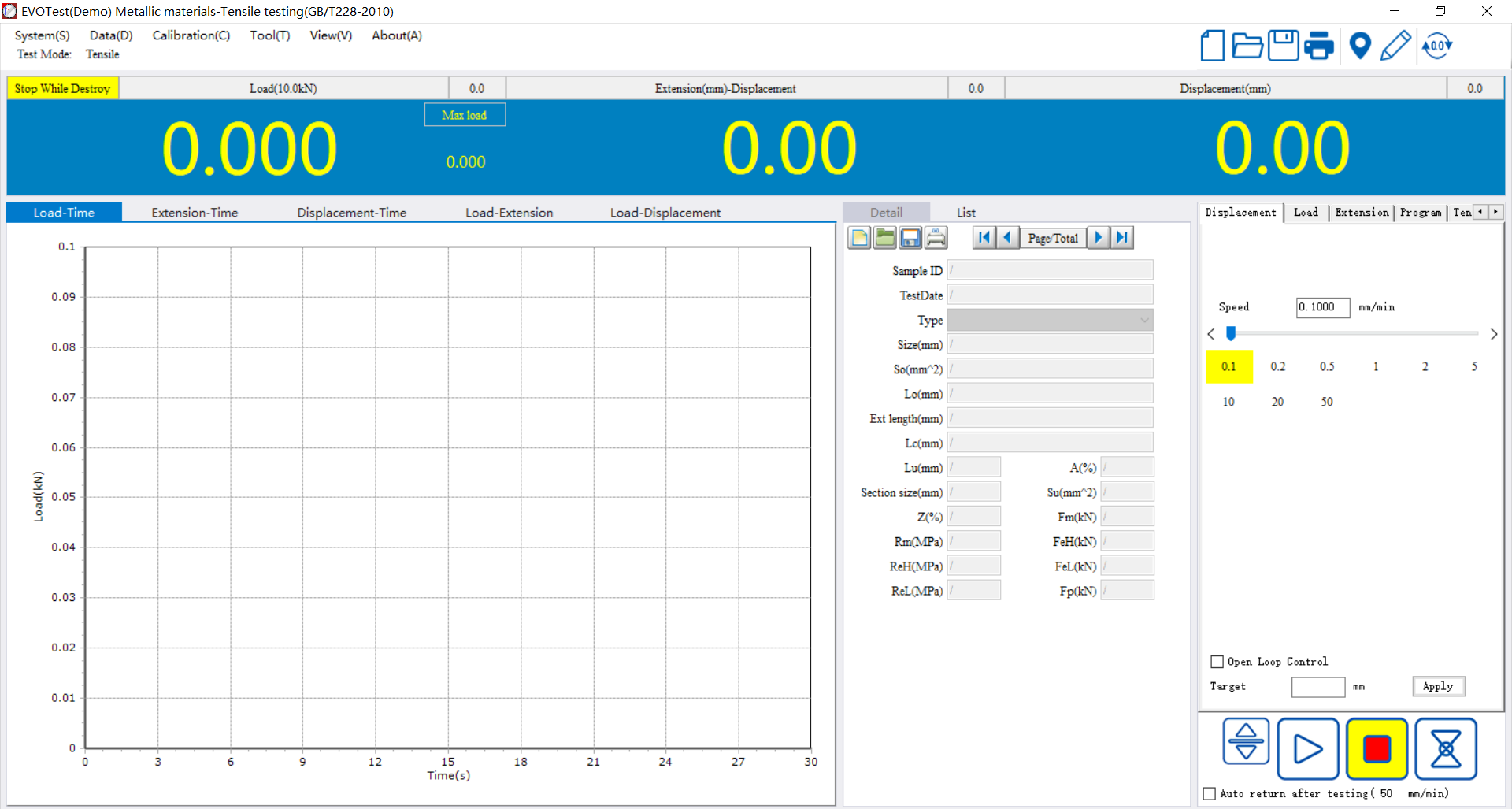

Controlling System

The force measuring element of the product is a high-precision load sensor, and the displacement measuring element is a high-precision pull-out displacement sensor. Load sensor, displacement sensor, all digital closed-loop control system and computer plus servo hydraulic system constitute a closed-loop measurement control operating system. Therefore, various test procedures can be set and selected, the test process can be automatically and accurately controlled, and the test parameters of each stage can be measured automatically, which ensures the high precision of the test. Test process curve should be displayed real time on both LCD touch screen & PC simultaneously. Can show the force-time, displacement-time curves.

The special test software installed and used is developed under the windows platform to ensure the test operation is simple and universal, the processing, storage and transmission of test data are easy and convenient, and the test process curve is displayed on the display in real time.

The system can realize long-time continuous and fast loading, holding and unloading, constant speed loading, long-time holding load, constant speed unloading, constant speed displacement and other closed-loop control.

The force and displacement can be controlled by sections in one test, and the control can be switched smoothly. The test parameters can be collected by computer and processed by software, and the test process can be controlled automatically and the test results can be obtained automatically. The test curves and results are displayed on the computer screen in real time, and the test reports and curves are printed by the printer.

The test software can be set and completed according to the test methods and standards specified by ISO and ASTM, or set and complete the test in advance according to the test methods and standards provided by customers according to the requirements of customers. The test data can be connected with the network through the data interface, and the network interface can be set in advance according to the user's requirements in the software, and the user can be assisted in networking work. it can be used in windows 10.

There are also limit protection devices, such as leakage protection, cut-off protection device, limit switch, emergency stop button, etc.

Electrical system

The power supply from the power distribution box to each machine shall be fixed along the wall and laid with wiring pipes.

The electric control part is equipped with manual switch

Packing list

The main frame (cylinder drawing) of 3500kn high rigidity horizontal tensile testing machine;

Full enclosed protective cover (solid steel plate, hydraulic opening and closing)

zHigh precision bidirectional electro-hydraulic servo proportional valve (ATOS, Italy)

High precision high-pressure gear pump (Mazuzi, Italy)

High precision load cell

High precision displacement

Test fixture: hydraulic clamping type

Hydraulic Tensile Grip

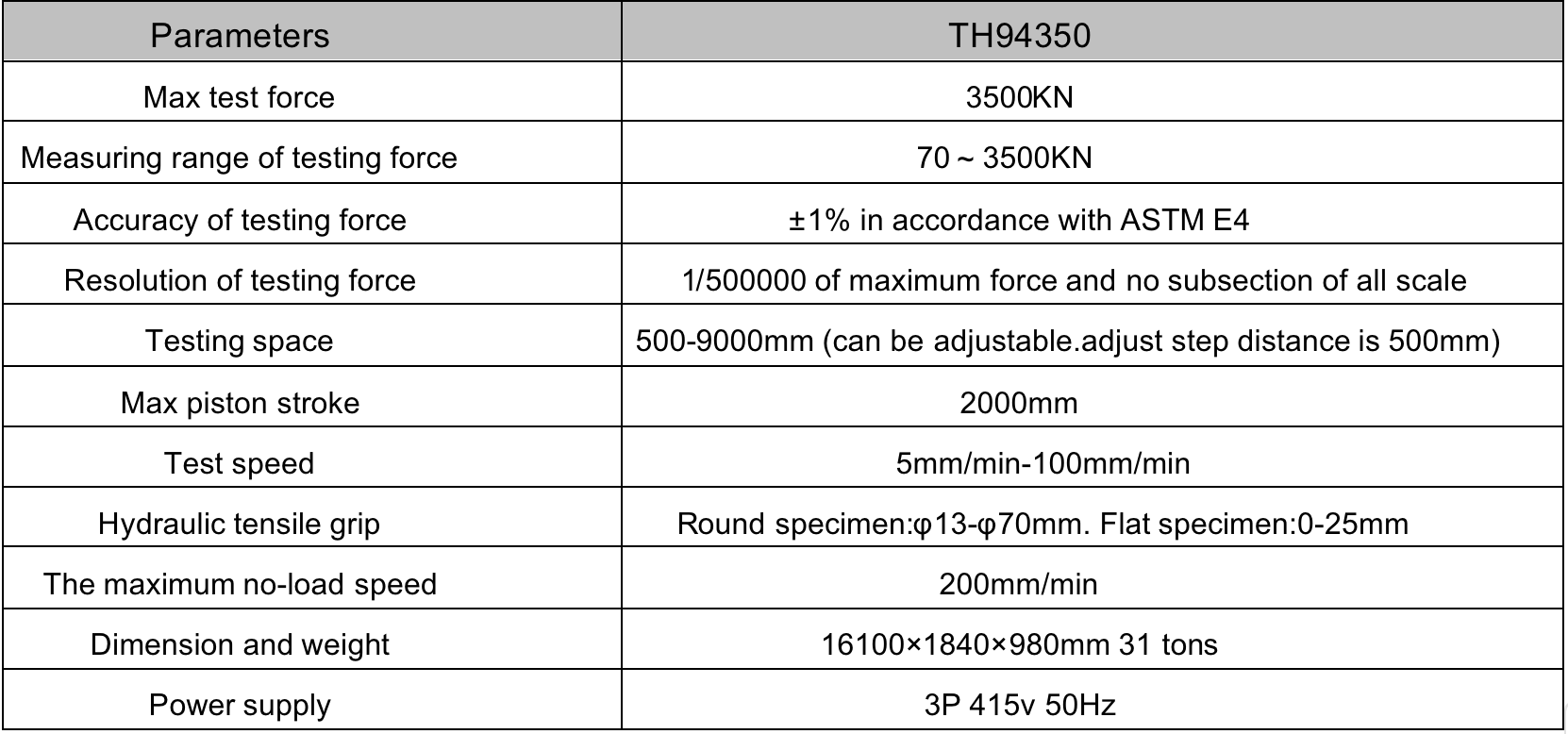

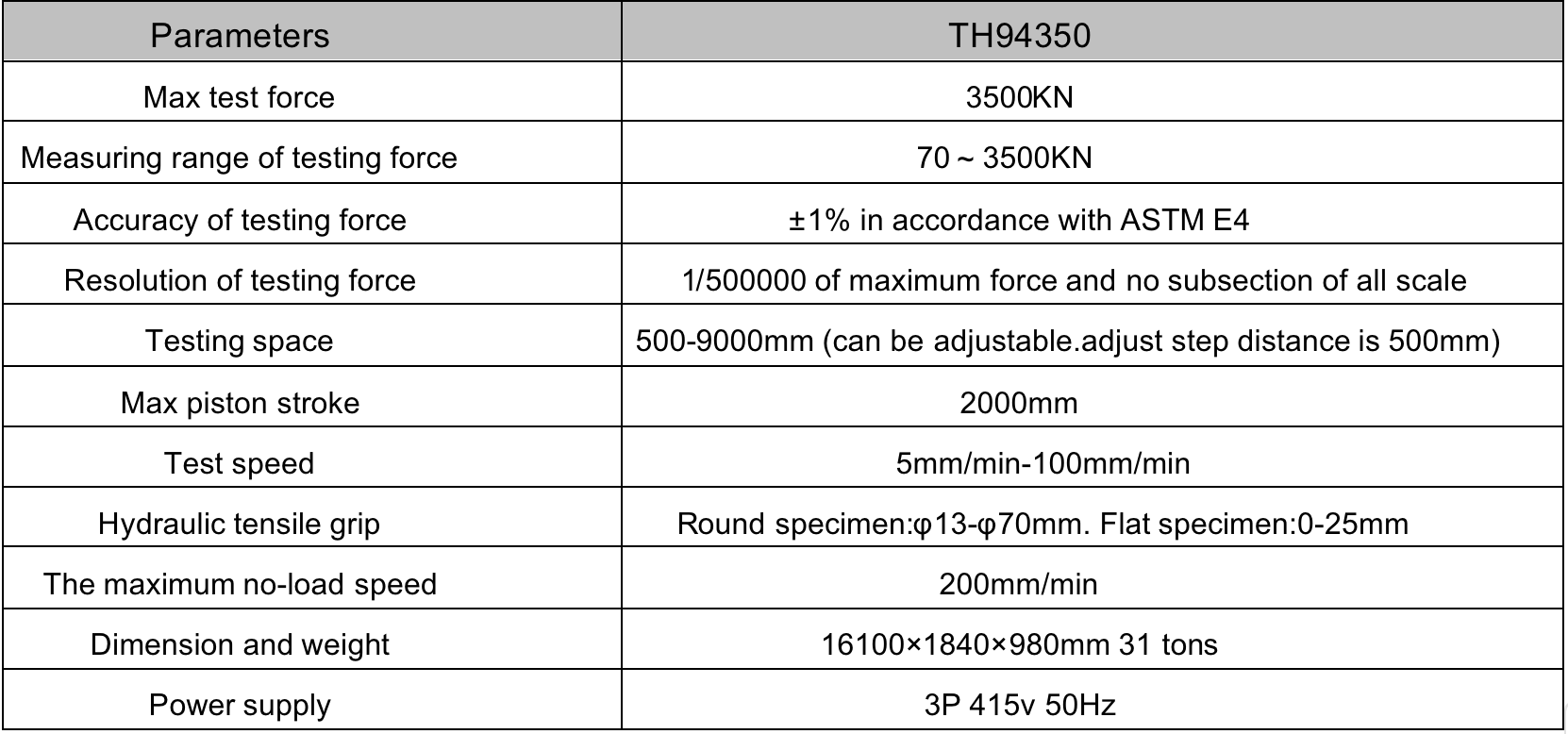

Specification

Standard measurement and control system

1.Full digital closed-loop control system

2.Special test software (English version);

3.One HP desktop business computer and one HP printer;

4.Integrated measurement and control operation cabinet

A set of software backup and related operation manual

The computer controlled electro-hydraulic servo horizontal testing machine is a kind of special high-precision testing equipment which is suitable for the tensile test , break test ,cyclic test, proof load ,elongation measurement of chain, rope, steel wire rope and electric fittings. The equipment can realize automatic operation, and the test can be completed automatically by computer software. The equipment uses load sensor and spherical centering device, and then consists of thrust cylinder, frame, lifting platform, etc. The equipment is driven by special power hydraulic source, electro-hydraulic servo control technology, computer data acquisition and processing, which can realize full-automatic closed-loop control. The equipment is composed of test host, oil source system (hydraulic power source), measurement and control system, electrical system, etc.

Main Structure Introduction

1.The main machine adopts horizontal frame structure, the stroke of oil cylinder is 2000mm, and the maximum testing space is 9000mm. The two beams with tensile fixture, fixed beam and thrust beam are precision processed with steel plate. The truss is welded with thick steel plate and processed on horizontal machining center. All auxiliary tools are finished after heat treatment of alloy steel. The overall design bearing capacity of frame structure is 5000kn, which ensures the precision, stability and reliability of the testing machine.

2.The adjustment of tensile test space is realized by moving the remote beam back and forth. For electric remote control, the beam movement can be controlled by close micro motion to make the positioning more accurate. At the same time, there is no need for manual pushing, which is fast and labor-saving. The two ends of the bolt are inserted vertically into the guide rail and the remote crossbeam by manual assistance. The operation of the bolt realizes the beam positioning and completes the space adjustment of the testing machine. It is very convenient to adjust the step distance of 500mm.

3.The high-precision load sensor used in the main engine has high comprehensive accuracy, high sensitivity and good repeatability. After random calibration, the test will not be affected by external orce, which can ensure the accuracy of the test process and parameters. Calibration and calibration are simple and convenient.

4.The machine design has been fully considered in terms of beauty, convenience and safety. For example: the test space adjustment is convenient and fast; the special fixture clamping is reliable; all parts of the testing machine are strictly antirust treated, and the surface of the pull rod is plated with hard chromium, polished and rustproof, so as to ensure the quality and beauty of the equipment, so as to satisfy the customers

Hydraulic Power System

1.The integrated oil source cabinet is composed of hydraulic pump station, oil source control, host control and computer host, which is convenient for operation, maintenance, protection and transportation. Computer, display screen and printer can be placed in the integrated measurement and control cabinet, with neat layout and space saving. The maximum working pressure of oil source system can reach 25MPa and 30MPa respectively.

2.The oil cylinder adopts the bi-directional control oil cylinder with multi-channel sealing, and the main force of the oil cylinder is the jacking force. The cylinder barrel and piston are made of high strength wear-resistant materials, which will not deform, wear and leak for a long time. High quality imported sealing ring, wear ring and dust ring are selected as sealing elements.

3.The power source adopts imported high-pressure gear pump to ensure stable system pressure and stable oil cylinder operation during long-term use. Energy saving, reliability, safety and environmental protection are fully considered in the system design. The oil source system adopts the components that meet the requirements of environmental protection.

4.The whole system adopts servo closed-loop control, high response servo valve, motor torque and speed stability, directional valve, differential valve, one-way valve, differential valve, etc, The valve core has fast response and high sensitivity, so it has good tracking, follow-up, adjustable and other functional characteristics. Under the control of high-performance measurement and control system, accurate closed-loop control is realized to ensure the test speed. It is a hydraulic servo control system with the most advanced technology, the best quality and the most high-grade configuration in the domestic testing machine.

5.The system is equipped with high-density hydraulic oil filtering system to ensure the cleanliness of medium oil under any conditions, and better ensure the optimal functional state of each hydraulic valve and servo valve;

6.The pressure self-protection function of hydraulic system ensures the potential danger caused by accidents, with high safety and reliability of human and machine.

Controlling System

The force measuring element of the product is a high-precision load sensor, and the displacement measuring element is a high-precision pull-out displacement sensor. Load sensor, displacement sensor, all digital closed-loop control system and computer plus servo hydraulic system constitute a closed-loop measurement control operating system. Therefore, various test procedures can be set and selected, the test process can be automatically and accurately controlled, and the test parameters of each stage can be measured automatically, which ensures the high precision of the test. Test process curve should be displayed real time on both LCD touch screen & PC simultaneously. Can show the force-time, displacement-time curves.

The special test software installed and used is developed under the windows platform to ensure the test operation is simple and universal, the processing, storage and transmission of test data are easy and convenient, and the test process curve is displayed on the display in real time.

The system can realize long-time continuous and fast loading, holding and unloading, constant speed loading, long-time holding load, constant speed unloading, constant speed displacement and other closed-loop control.

The force and displacement can be controlled by sections in one test, and the control can be switched smoothly. The test parameters can be collected by computer and processed by software, and the test process can be controlled automatically and the test results can be obtained automatically. The test curves and results are displayed on the computer screen in real time, and the test reports and curves are printed by the printer.

The test software can be set and completed according to the test methods and standards specified by ISO and ASTM, or set and complete the test in advance according to the test methods and standards provided by customers according to the requirements of customers. The test data can be connected with the network through the data interface, and the network interface can be set in advance according to the user's requirements in the software, and the user can be assisted in networking work. it can be used in windows 10.

There are also limit protection devices, such as leakage protection, cut-off protection device, limit switch, emergency stop button, etc.

Electrical system

The power supply from the power distribution box to each machine shall be fixed along the wall and laid with wiring pipes.

The electric control part is equipped with manual switch

Packing list

The main frame (cylinder drawing) of 3500kn high rigidity horizontal tensile testing machine;

Full enclosed protective cover (solid steel plate, hydraulic opening and closing)

zHigh precision bidirectional electro-hydraulic servo proportional valve (ATOS, Italy)

High precision high-pressure gear pump (Mazuzi, Italy)

High precision load cell

High precision displacement

Test fixture: hydraulic clamping type

Hydraulic Tensile Grip

Specification

Standard measurement and control system

1.Full digital closed-loop control system

2.Special test software (English version);

3.One HP desktop business computer and one HP printer;

4.Integrated measurement and control operation cabinet

A set of software backup and related operation manual

Loading...